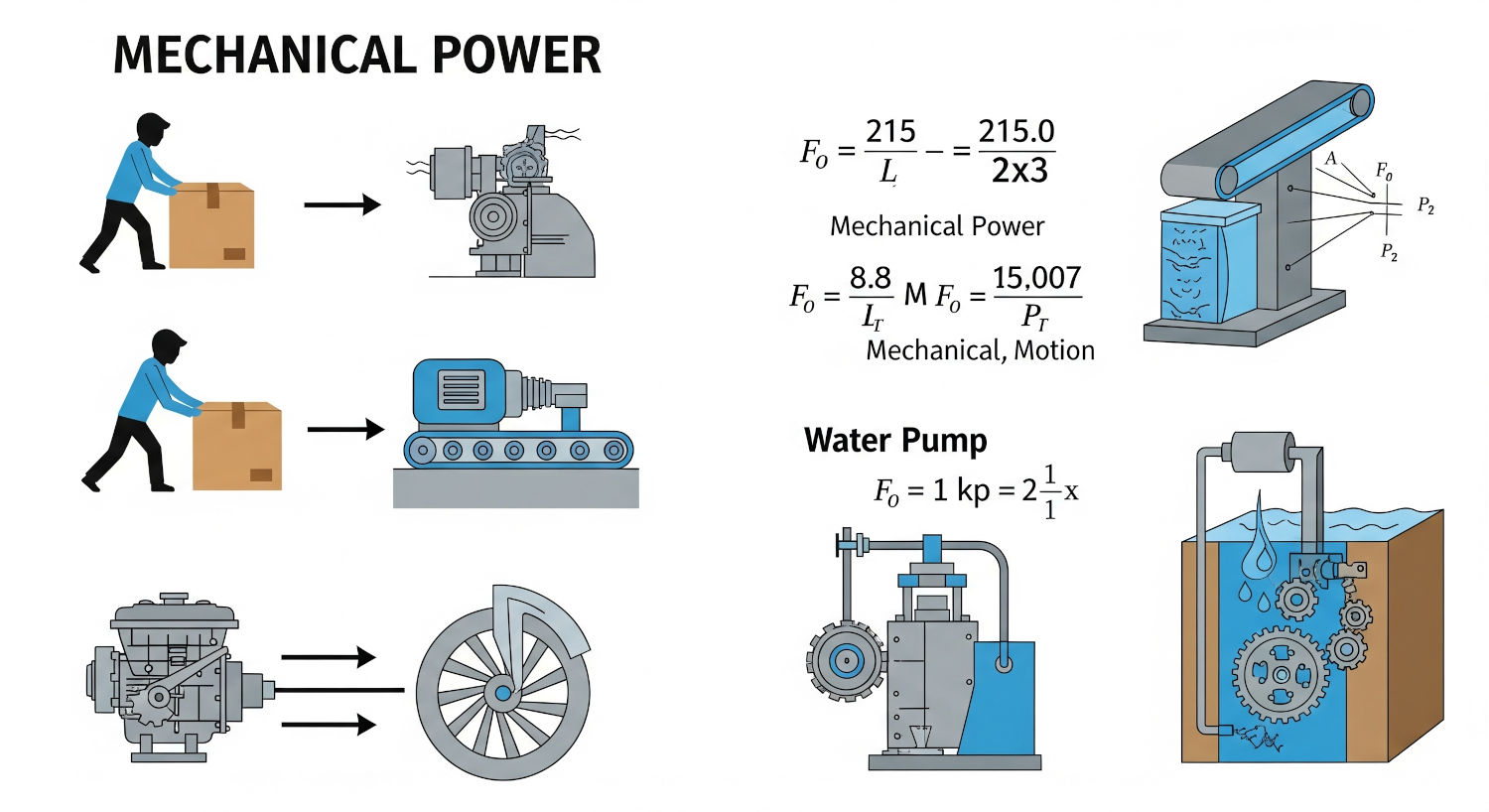

- Mechanical power measures the rate at which work is done or energy is transferred in both linear and rotational systems.

- Equations for mechanical power involve the relationship between force and velocity for linear motion, and torque and angular velocity for rotational motion.

- Mechanical power transmission is essential in engineering, enabling the transfer, conversion, and adaptation of power across distances and different machine components.

Mechanical power is all around us, driving everything from a cyclist’s pedal stroke to the rotation of massive industrial machines. Despite its everyday presence, the underlying science that dictates how power is transferred, harnessed, and measured in our world is both nuanced and fascinating. Whether you’re taking apart an old engine, wondering how wind produces electricity, or just curious about what makes energy flow in machines, understanding mechanical power is the key to making sense of it all.

Let’s dive into this concept and break it down in an accessible way. This article will guide you through the definitions, equations, types, and real-world implications of mechanical power—exploring both the physics and practical aspects, all wrapped in a clear, approachable tone. By the end, you’ll know exactly what mechanical power is, how it’s calculated, why it matters, and how it shapes the technology and motion of our everyday lives.

What Is Mechanical Power?

At its core, mechanical power is the rate at which work is done or energy is transferred by mechanical means. Think of it as a measure of “how fast” energy is converted into motion, or how quickly a machine or force does its job. When you push a box, lift a weight, spin a gear, or ride a bike, you’re delivering mechanical power.

Mechanical power is a time-based measurement—it answers the question: How much energy or work is being transferred each second? In the International System of Units (SI), the unit for power is the watt (W), named after James Watt of steam engine fame. One watt is simply one joule (unit of energy) per second.

But wait, what is meant by “mechanical” specifically? Mechanical power refers only to energy transferred by mechanical forces or movement—like lifting, pushing, spinning, or pulling—rather than electrical or chemical means.

Key Definitions and Equations

Let’s get into the nitty-gritty: the equations and physical quantities that define mechanical power.

- Work (W): The process of applying force over a distance. If you push a cart and it moves, you’ve done work. In simple terms, work = force × distance.

- Power (P): The rate at which work is done, or energy is transferred. The basic formula: P = W / Δt, where Δt is the time interval.

In mechanical systems, there are two main ways to express power, depending on the type of motion:

- For linear (straight-line) motion:

P = F × v

Here, F is the applied force (in the direction of motion), and v is the velocity. - For rotational (circular) motion:

P = τ × ω

Where τ (tau) is the torque (rotational force), and ω is the angular velocity (how fast something spins, in radians per second).

In both equations, power increases if either the force (or torque) or the speed increases. This makes sense: more force or more speed both mean “more work per second.”

Digging Deeper: Components and Characteristics of Mechanical Power

Power is a “scalar” quantity—it’s only described by a magnitude (number), not a direction. This makes it easy to add up powers from different sources or parts of a system.

Mechanical power can be both input and output: For example, a car engine’s fuel delivers input power, some of which is lost as heat, leaving less mechanical output power at the wheels. This input-output distinction is crucial for understanding efficiency and the losses in any real-world machine.

Mechanical power is measured in:

- Watts (W): The standard SI unit. 1 W = 1 joule/second.

- Horsepower (hp): Often used for engines and motors; 1 mechanical horsepower ≈ 745.7 W.

- Other units include ergs per second, foot-pounds per minute, and BTU per hour (in English/US customary systems).

Kinds of Mechanical Power: Linear and Rotational

In the real world, machines often involve both types of motion: things move in straight lines and also rotate. Here’s how mechanical power shows up in both contexts:

1. Translational (Linear) Power

Translational power deals with things moving in a straight line, like elevators, conveyor belts, or a winch lifting a crate. The governing formula, as mentioned above, is P = F × v.

- The force (F) is applied in the direction of the movement.

- The velocity (v) is how fast the object moves along that direction.

If you want to move a heavier object at the same speed, you need more power. Conversely, to move the same weight faster requires more power as well.

2. Rotational (Angular) Power

Rotational or angular power governs machines with spinning parts: motors, turbines, bicycle wheels, and drills.

- P = τ × ω describes how much power is being supplied.

- Torque (τ) is like a “rotational force,” a measure of how strongly something is being twisted.

- Angular velocity (ω) tells us how fast something is spinning (in radians per second).

Alternatively, in certain setups (like winches or gearboxes), you may see P = 2π × n × M, where n is the number of revolutions per second/minute and M is the torque. It’s just another way to express the same idea, with angular speed in familiar “RPM.”

Principle of Energy Conservation in Mechanical Power

One of the most fundamental ideas in physics is that energy cannot be created or destroyed, only transferred or converted. This is the principle of conservation of energy. For machines and mechanical systems, it means that the power you put into a system (like turning a crank, or burning fuel) must either come out as useful work (lifting, spinning, pushing) or else be lost as heat, sound, vibration, or friction.

This leads to the idea of efficiency: no real-world device is perfect. If a machine receives 100 W of mechanical power, some of that power will be lost on the way to the output. The ratio of output to input power is the efficiency, often given as a decimal or percentage.

Mechanical Power Transmission: Moving Power Where It’s Needed

Mechanical power doesn’t always get used where it’s generated. That’s where mechanical power transmission comes in—it’s the collection of methods and elements used to transfer power from one place to another, adapt its form, or distribute it to multiple devices.

What is Mechanical Power Transmission?

Mechanical power transmission involves using components—like shafts, gears, belts, chains, and couplings—to move and adapt energy throughout machines or systems. It’s essential in virtually every machine, from cars and bikes to industrial robots and massive conveyor systems.

- Shafts and Couplings: Shafts transfer rotary motion from one component to another, often connected by couplings that allow for some flexibility or alignment correction.

- Gears and Gear Trains: Gears change the speed, torque, and direction of power—letting you, for example, climb a hill in a low gear on your bike or turn the slow rotation of a wind turbine into high-speed generator motion.

- Belts, Ropes & Pulleys: These transmit power over distances where shafts or gears are impractical, like in some factory machines.

- Chains & Sprockets: Common in bicycles and industrial machines, chains offer positive engagement (no slip) and can handle higher torque than belts.

- Brakes & Clutches: These control the flow of mechanical power—stopping, starting, or regulating how much power gets through in a system.

- Power Screws: Used to convert rotary motion to linear, like in jacks or vises.

The key benefit of mechanical transmission elements is their ability to adapt and channel power efficiently—adjusting for speed, force, or direction as required by different machine operations.

Why Is Mechanical Power Transmission Important?

- Power can be generated in one place and delivered where it’s needed—even if the source is far away.

- Mechanical elements can change the magnitude, speed, or form of power to fit specific tasks. For example, a gearbox in your car lets the engine operate efficiently at various speeds.

- Systems can be designed for safety, efficiency, and ease of maintenance.

Mechanical power transmission is absolutely vital in engineering and product design, determining how motors, engines, and other sources connect to the rest of a machine for optimal operation.

The Physics: Work, Force, and Energy Relationships

Understanding the underlying physics helps clarify how mechanical power really works. Here are the main relationships:

- Work (W): The result of applying a force (F) across a distance (Δs): W = F × Δs.

- Power (P): The time rate of doing work: P = W / Δt.

- For motion: P = F × v for linear, P = τ × ω for rotational.

When you vary the force or speed, you also affect the mechanical power supplied (or needed). For instance, a heavier object can only be lifted if you use more power, or if you lift it more slowly with the same power.

Mechanical Power in Real Life: Examples and Applications

Let’s look at where mechanical power appears in everyday life and industry.

Transportation and Vehicles

- Cars and Trucks: The engine converts fuel energy into mechanical power delivered through a complex transmission to the wheels. More power means faster acceleration or the ability to haul heavy loads.

- Bicycles: Pedaling produces power that’s transmitted to the rear wheel via chain and gears. Lower gears allow more torque (force) for climbing hills at lower speeds.

- Airplanes: Jet engines deliver mechanical power to propel the aircraft forward, overcoming drag and enabling flight.

Industry and Manufacturing

- Pumps and Compressors: Mechanical power is used to move fluids in industrial and municipal systems—rotational power from a motor is turned into fluid movement via a shaft and impeller.

- Wind Turbines: Wind turns the blades, spinning a shaft. Mechanical power is then converted into electrical power by a generator.

- Construction Equipment: Cranes, winches, and excavators rely on mechanical power to lift, move, or dig heavy loads.

Home and Everyday Technology

- Appliances: Blenders, washing machines, and fans all operate by converting electrical energy into mechanical power to create motion.

- Tools: Drills, saws, and other hand tools transform your effort (or an electric motor’s effort) into mechanical power to do work.

Relationship Between Mechanical Power, Kinetic and Potential Energy

Mechanical energy is the sum of kinetic energy (energy due to motion) and potential energy (energy due to position or configuration). Mechanical power is not the same as mechanical energy, but the two are related.

- Kinetic Energy: Energy that comes from motion—like a moving car or a spinning flywheel.

- Potential Energy: Stored energy due to position—like a lifted weight or compressed spring.

Mechanical power reflects the speed at which energy is transferred or changes within a system. For example, a roller coaster descending converts potential to kinetic energy rapidly, resulting in high mechanical power during that phase.

Mechanical Power and Energy Conversion

Mechanical power is often a step in a chain of energy conversions. For instance, a fuel-powered engine turns chemical energy to heat (thermal), heat to mechanical power, and then that mechanical power may be partially transformed again into electrical energy (via a generator), movement, heat, sound, or even light.

Real-world machines aren’t perfect—some mechanical power is always lost through friction, heat, or other inefficiencies. That’s why car engines get hot, or why turbines need lubrication and cooling.

Mechanical Power Transmission Elements: More Details

Each component in a mechanical transmission system is designed for specific functions and types of loads. Here’s a breakdown:

Shafts and Couplings

- Shafts transmit rotational power from one part of a machine to another.

- Couplings connect two shafts, allowing slight misalignments and flexibility.

- Important considerations include torque, speed, shaft size, and direction of rotation.

Gears and Gear Trains

- Gears transfer and adapt mechanical power, changing speed and force. Gear trains can provide a mechanical advantage, letting a small input force move a much larger load.

- Gear ratios define the relationship between input and output speed/force.

Belts, Ropes, and Pulleys

- Belts and pulleys are used for transferring power over larger distances when gears would be too bulky or when design flexibility is needed.

Chains and Sprockets

- Chains are ideal for positive, slip-free transmission over short distances, allowing for precise speed ratios and strong torque handling.

Brakes and Clutches

- Brakes stop or slow down moving machine parts, dissipating mechanical power as heat.

- Clutches engage or disengage power transmission between shafts, enabling control over when and how power flows in a system.

Efficiency and Energy Losses in Mechanical Power Systems

No mechanical system is 100% efficient—energy losses are inevitable due to friction, heat, sound, and other factors.

- Friction in shafts, gears, and bearings always dissipates some mechanical power as heat.

- Transmission efficiency is a key metric in engineering—a well-designed gearbox or belt system can transfer 90–98% of input power, while poorly maintained systems can lose much more.

Understanding and minimizing these losses is crucial to maximizing useful output from any machine or system. Regular maintenance (like proper lubrication and alignment) helps reduce unnecessary losses and prolongs equipment life.

Real-World Problems and Practical Tips

Several practical considerations come into play in the real world:

- Power Limitations: Every motor or engine has a maximum mechanical power output. Overloading a system can cause overheating or damage.

- Transmission Ratios: Gears, pulleys, and gearboxes don’t multiply power—they trade off force for speed (or vice versa) while keeping power nearly constant apart from losses.

- Matching Power to Application: Choosing the right mechanical power components for a task ensures efficient, reliable operation.

Examples: Calculating Mechanical Power

Let’s see some simple calculations in action.

Example 1: Lifting a Weight

You use a winch to lift a 50 kg crate vertically at a speed of 0.5 m/s. How much mechanical power is required (ignoring losses)?

- First, calculate the force (F): F = mass × gravity = 50 kg × 9.81 m/s² ≈ 490.5 N

- Then, P = F × v = 490.5 N × 0.5 m/s = 245.25 W

About 245 watts of mechanical power are needed to lift the crate at that speed.

Example 2: Rotating a Shaft

A machine spins a shaft with a torque of 10 Nm at 300 revolutions per minute (RPM). What’s the mechanical power output?

- First, convert RPM to radians/second:

300 RPM × 2π / 60 ≈ 31.42 rad/s - Then, P = τ × ω = 10 Nm × 31.42 rad/s ≈ 314.2 W

Example 3: Efficiency with Losses

An electric motor delivers 500 W of input power to a conveyor system. If the system has an 85% efficiency, what is the output mechanical power?

- Output power = Input power × efficiency = 500 W × 0.85 = 425 W

That’s the amount of power actually transferred to move items on the conveyor.

Mechanical Power In Renewable Energy

Mechanical power plays a vital role in many renewable energy systems. Wind, water (hydropower), and steam turbines all harness moving fluids to generate electrical power.

- Wind Turbines: The kinetic energy of wind spins blades, producing rotational mechanical power that’s then converted into electricity by a generator.

- Hydropower: Flowing water’s energy is captured by turbines, spinning them and generating mechanical (then electrical) power.

- Steam Turbines: High-pressure steam from boilers spins turbine blades—the mechanical power turns a generator shaft, making electricity.

Each system is designed to maximize the mechanical power extracted from its environmental source.

Frequently Asked Questions About Mechanical Power

- Is mechanical power the same as mechanical energy?

No—mechanical power is about the rate of energy transfer or conversion, while mechanical energy is the total energy due to motion and position in a system. - How do you measure mechanical power?

With proper instruments like dynamometers, force sensors, torque sensors, and speed gauges, you can accurately measure the power output or input in real-world systems. - Can power be increased indefinitely?

No—every machine has design limits, and real-world losses mean efficiency drops if you push components too far. - What are the most common causes of power loss?

Friction, poor alignment, wear and tear, and inadequate lubrication are the main culprits.

All in all, mechanical power is an essential concept, not just for scientists but for anyone interested in how the modern world moves and works. By understanding how mechanical power is calculated, transmitted, and harnessed, you’ll gain insight into everything from pushing a shopping cart to the high-tech systems that power cities. From simple machines to the latest renewable energy technologies, the principles of mechanical power are deeply woven into the fabric of our lives, shaping how we design, build, and improve the tools and systems that keep the world in motion.