- Digital fabrication blends CAD design with automated manufacturing for high precision

- It involves both additive and subtractive methods such as 3D printing and CNC machining

- The technology is widely adopted in architecture, engineering, product design, and education

- Emerging materials and robotics are expanding the potential of digital fabrication

Imagine designing a product on your computer and hours later holding a fully formed version of it in your hands. That’s the essence of digital fabrication, a modern manufacturing process that merges design and production through advanced digital tools. Whether it’s a 3D-printed architectural model or CNC-machined custom furniture, digital fabrication is changing how we build, prototype, and innovate.

As industries push the boundaries of automation, precision, and sustainability, digital fabrication stands at the forefront of that evolution. With roots in manufacturing but applications spreading across architecture, engineering, art, and education, this technology offers powerful solutions far beyond simple prototyping. From creating artistic glass installations to building entire houses layer by layer, digital fabrication opens up possibilities few could have imagined a decade ago.

What is Digital Fabrication?

Digital fabrication refers to the process of turning digital files into physical objects through automated equipment guided by computer input. Central to this process are CAD (Computer-Aided Design) programs that provide the blueprint, and CAM (Computer-Aided Manufacturing) systems that translate these designs into machine-readable formats like G-code. The resulting instructions are used by machines such as 3D printers, CNC routers, and laser cutters to create tangible parts or structures.

Depending on the method, fabrication can be additive, subtractive, or robotic. Additive manufacturing includes 3D printing techniques that build objects layer by layer, while subtractive methods like CNC machining carve or cut material away. Robotic fabrication, using robotic arms and automation, allows for high-speed, repetitive actions, suited for complex construction or industrial purposes.

How Digital Fabrication Works

The journey from idea to object begins with a digital model, typically created using software like Autodesk Fusion 360, SOLIDWORKS, or Blender. Designers manipulate these models in a virtual environment to adjust shape, scale, materials, and tolerances before exporting them into machine-readable formats (commonly STL or OBJ files).

These files are then prepared by slicing software that converts the models into a set of instructions for the machine. It breaks down the design into horizontal layers and determines tool paths and speeds, depending on the machine used. Once uploaded into the fabrication equipment, the machine executes the build with little human intervention—from printing a prototype to carving wood or precision laser-cutting acrylic sheets.

Popular Digital Fabrication Techniques

There are several key technologies that fall under the digital fabrication umbrella, each with unique capabilities and applications:

3D Printing (Additive Manufacturing)

3D printing is perhaps the most recognizable form of digital fabrication and encompasses multiple techniques:

- Fused Deposition Modeling (FDM): Uses thermoplastic filament melted and deposited layer by layer through a nozzle. Common in hobbyist applications and small product prototyping.

- Stereolithography (SLA): Cures liquid resin using projected UV light to form solid objects. Offers exceptional detail, used in dental, jewelry, and product design.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered material (plastics, metals) layer by layer.

- Binder Jetting: Deposits a binder onto powdered materials (gypsum, metal, sand) to create models, used for producing colorful prints or metal parts.

Laser Cutting

Laser cutters use focused laser beams to slice or engrave materials like wood, acrylic, paper, and metals within extremely precise tolerances. Settings like power, speed, and resolution can be adjusted depending on desired depth and material type. It’s widely utilized in model building, sign making, packaging prototypes, and decorative art.

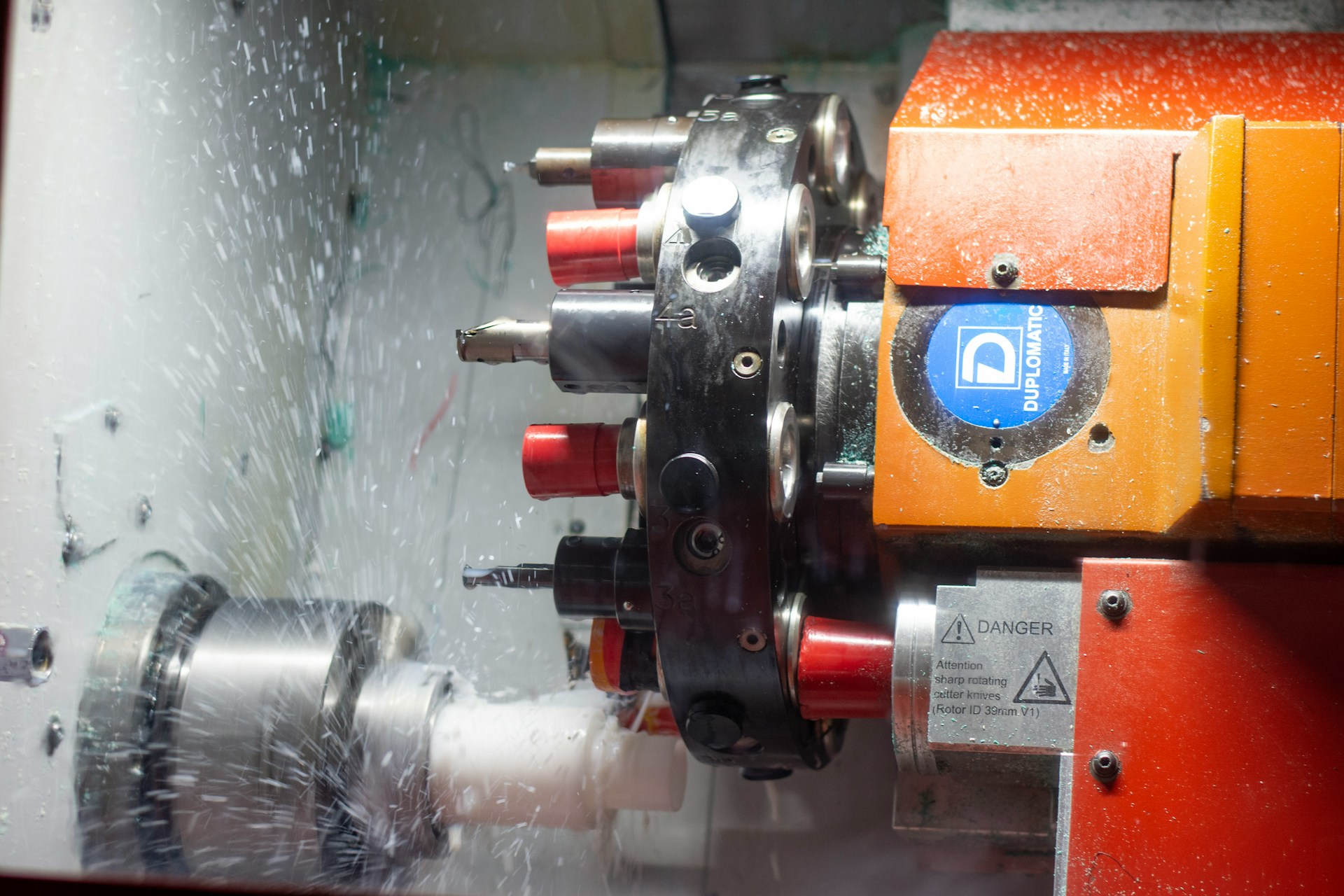

CNC Machining

CNC (Computer Numerical Control) machines work based on predefined tool paths to subtract material along one to nine axes. This includes operations such as milling, drilling, grinding, and turning. CNC machines are ideal for fabricating components in metal, wood, or foam, often used in aerospace, automotive, and construction applications.

Robotic Fabrication

This technique uses robotic arms or automated assemblies programmed to perform tasks such as welding, stacking, dispensing material, or placing bricks and components directly on-site. These systems can complete jobs that are dangerous or require extreme precision, opening up applications in automated construction and large-scale manufacturing.

Applications Across Industries

Architecture

Digital fabrication is revolutionizing architecture with prefab components, scaled models, and full-scale constructions. Firms now use this technology to produce precise facade elements, load-bearing components, or internal structures that would be time-intensive, expensive, or impossible using traditional tools. Notably, the MX3D Bridge in Amsterdam showcases steel 3D printing in public infrastructure, laying down complex geometries via robotic arms.

Another example includes custom glass components used for the curved exterior of Hamburg’s Elbphilharmonie, produced using CNC machines to match every panel exactly to its corresponding digital blueprint. Prototypes and small parts allow teams to test facades, joints, and installation methodology before committing to final materials.

Engineering

The engineering sector has long been a pioneer of digital fabrication for producing parts requiring exact tolerances and repeated iterations. Engineers utilize fabrication to automate complex parts, reduce human error, and improve consistency in both prototypes and production-ready components. Applications include metal frames, custom enclosures, robotics systems, and fluid containment components—all optimized using CAM and CAE software.

Product Design

From custom toys to ergonomic furniture, product designers embrace digital fabrication as a core part of creative workflows. Services like Bridgewater Studio specialize in translating visual concepts into working prototypes, combining scanning, modeling, and printing technologies. In one case, oversized product displays for apparel brand G/FORE were prototyped digitally, ensuring stakeholder alignment across remote locations before committing to build.

Rapid prototyping not only speeds up timelines but also unveils design flaws early. As engineer Sam Holland states at Onshape, “Printing a part lets me catch an issue in a day that might take months to fix if already molded.”

Art and Sculpture

Contemporary artists are integrating fabrication to reshape material exploration. Glass artists like Anjali Srinivasan at Haystack Fab Lab utilize 3D modeling and encoding tools to push the boundaries of glassworks beyond what the human hand can traditionally carve.

Education

Digital fabrication labs (Fab Labs) are now integral across schools and universities, giving hands-on experience in practical engineering and design workflows. Students learn about problem-solving, manufacturing cycles, and sustainability using small 3D printers and cutters. This democratizes access to technology and nurtures a new generation of makers and innovators.

Common Materials in Fabrication

The choice of material influences every aspect of the fabrication process, including cost, functionality, and durability. Some of the most widely used materials include:

- Thermoplastics: PLA, ABS, and TPU are common in 3D printing, offering flexibility, biodegradability, and color options.

- Metals: Stainless steel, aluminum, and copper are used in CNC machining and industrial-grade 3D printers for structural or functional parts.

- Wood: Plywood and MDF are suitable for laser cutting and CNC routing, producing furniture or decorative panels.

- Glass and Concrete: Emerging techniques now combine robotic mixing and extrusion to produce fine concrete shell structures or novelty glass pieces.

Software Ecosystem

Software is the foundation of digital fabrication. Professionals typically use a combination of programs with different purposes:

- Modeling: AutoCAD, Rhinoceros 3D, SolidWorks, and 3ds Max for geometry creation

- Animation and Simulation: Blender, ZBrush for testing movement or sculptural aesthetics

- CAM Slicing: Cura, PrusaSlicer, or proprietary CNC software to convert models to build instructions

Workflow Considerations

To succeed in digital fabrication, designers must first plan constraints, timelines, and resources. Understanding the function of the part, fabrication method, and available materials is crucial early in the project. Starting with virtual walk-throughs and 3D environments helps stakeholders visualize concepts clearly.

Once input files are ready, production facilities customize the process per equipment via CAM interfaces. Parts may go to 3D printers, CNC routers, or laser cutters depending on geometry and tolerances required. Hybrid workflows—3D printing a model and complementing with milled metal brackets—are common in complex builds like interactive furniture or robotics kits.

Advantages and Limitations

Digital fabrication offers a ton of benefits over traditional manual methods. Some key advantages include:

- Precision: Machines follow exact digital models, ensuring consistency across batches

- Speed and Iteration: Designers can rapidly modify files and remake parts within a day

- Reduced Waste: Material consumption is optimized since machines deposit or remove only what’s needed

- Labor Savings: Automation replaces repetitive or hazardous jobs, allowing focus on creative or supervisory roles

Challenges include equipment costs, design complexity, and material constraints, which can limit immediate adoption or require investment in training and upgrades.

The Road Ahead

Digital fabrication technologies continue to evolve, shaped by AI, sustainability, and materials science. Future applications in prefabrication, bio-fabrication, and smart robotics promise even wider adoption across industries. Building Information Modeling (BIM) integration ensures seamless transitions between architectural planning, structural analysis, and production files.

If you’re curious about diving deeper, institutions like ICD at Universität Stuttgart and platforms like Parametric Architecture explore cutting-edge research and applications of digital construction technologies. This convergence of computational creativity, automation, and accessibility signals a new era where function and form are dictated more by imagination than manufacturing limitations.