- The nature and types of friction: static, kinetic, fluid, and more

- Microscopic origins and modern theories explaining frictional forces

- Practical applications, instabilities, and innovations in friction management

Friction plays a subtle yet profound role in the physical world, shaping everything from the way we walk to the functionality of complex machinery. Despite being ever-present, friction is so intertwined with daily life that its mechanisms and implications are frequently underestimated or misunderstood. Whether you’re gliding across an icy pavement or pondering why engines waste so much energy, friction’s influence is both a marvel and a challenge for engineers, scientists, and the curious alike.

Delving into friction theory not only unravels the physical forces behind everyday phenomena but also reveals a web of intricate principles that continue to puzzle, inspire, and push the boundaries of scientific insight. From ancient philosophers to pioneering physicists and modern engineers, countless thinkers have attempted to decode this fundamental force. This article is an in-depth journey through the science, history, applications, and recent developments of friction theory, translating comprehensive research, technical documentation, and contemporary perspectives into an engaging resource.

Understanding Friction: A Multifaceted Force

Friction is, at its core, a resistance to motion whenever two surfaces, layers, or elements come into contact and move relative to one another. This phenomenon is ever-present, governing the ease or difficulty with which objects slide, roll, or even rest upon each other. The force of friction can be observed in many scenarios: it’s why you don’t slip when walking, why machines overheat, and even why it’s challenging to move a large piece of furniture from one spot to another.

But friction is no simple adversary of motion. It is an enabler of essential activities and technological functions. The traction needed for walking, the grip between tires and the road, and the very act of striking a match are all made possible by frictional forces. Yet, it is equally well-known for being an obstacle: a source of wear and the bane of mechanical efficiency, responsible for a significant percentage of energy lost in engines and industrial processes.

The Types and Nuances of Friction

Friction manifests in several distinct forms, each with unique characteristics and implications:

- Dry Friction: The resistance encountered when two solid surfaces slide against each other, subdivided into static and kinetic (sliding) friction.

- Fluid Friction: This occurs between layers of a fluid (liquid or gas) as they move relative to one another. Viscosity is a measure of a fluid’s internal resistance to flow.

- Lubricated Friction: A special case of fluid friction, prevalent when a lubricant separates two solid surfaces, reducing direct contact and, consequently, friction.

- Skin Friction: Resists the movement of a fluid along the skin or surface of a solid body—critical in aerodynamics and hydrodynamics.

- Internal Friction: The resistance within a deforming solid, as its constituent particles are displaced relative to each other.

- Rolling Friction (Rolling Resistance): When an object rolls over a surface, the deformation at the contact point creates resistance, typically much lower than sliding friction.

- Radiation Friction: A theoretical concept where the movement of objects in a radiative field (like light) experiences opposing pressure, as discussed by Einstein.

- Belt Friction: Observed when a flexible belt or rope moves around a pulley, critical in machinery and navigation.

Each type of friction emerges from a complex interplay of surface features, material properties, environmental conditions, and the forces at play. Whether it involves atomic-scale adhesion, deformation, or the generation of heat and even electrostatic charges, no universal theory covers every situation, making friction both fascinating and notoriously difficult to predict.

Historical Journey: From Ancient Curiosity to Modern Science

Human fascination with friction stretches back millennia, deeply rooted in attempts to start fires, build machines, and explain mysterious resistances. Ancient thinkers like Aristotle and Vitruvius pondered its causes, while Themistius was among the first to distinguish between a body at rest and one already in motion—recognizing that it is easier to keep an object moving than to start its movement.

Leonardo da Vinci, centuries ahead of his time, meticulously documented the basic laws of sliding friction in the late 1400s, but his revelations remained hidden in his notebooks for generations. Rediscovered by Guillaume Amontons in the 17th century, these principles laid the groundwork for what became known as Amontons’ laws of dry friction:

- The force of friction is proportional to the applied load.

- The force of friction is independent of the apparent area of contact.

- Kinetic (sliding) friction remains consistent regardless of the sliding velocity (Coulomb’s law).

Progress continued through the Enlightenment, with physicists like de Coulomb, Euler, Desaguliers, and later Joule, Reynold, and Planck providing mathematical foundations and experimental insight. From investigating rolling friction to quantifying the conversion of mechanical work into heat, their collective work established friction as a central concept in thermodynamics and mechanics.

Microscopic and Molecular Mechanisms of Friction

Modern advances have revealed that friction is far from a monolithic phenomenon. Instead, it is the byproduct of interactions at the atomic and molecular scale. At the surface, minuscule protrusions (asperities) make real contact at only a tiny fraction of the objects’ apparent area. The actual area increases under greater load, and it’s these limited points—where bonding, deformation, and molecular forces like van der Waals come into play—that account for the observed friction.

Research using atomic force microscopy has made it possible to measure and visualize friction at the nanoscale, solidifying the connection between inter-surface shear stress and contact area. This underpins Amontons’ first law by showing that the macroscopic friction force remains proportional to the normal load applied, even though the underlying atomic interactions are intricate and variable.

Recent microscopic theories also highlight the surprising importance of surface impurities—grime, dust, adsorbed water, and molecular debris—all of which mediate or even dominate frictional forces by preventing perfectly smooth surfaces from sliding freely. These subtle contaminants can ‘lock’ surfaces together in ways models of idealized clean surfaces simply cannot predict.

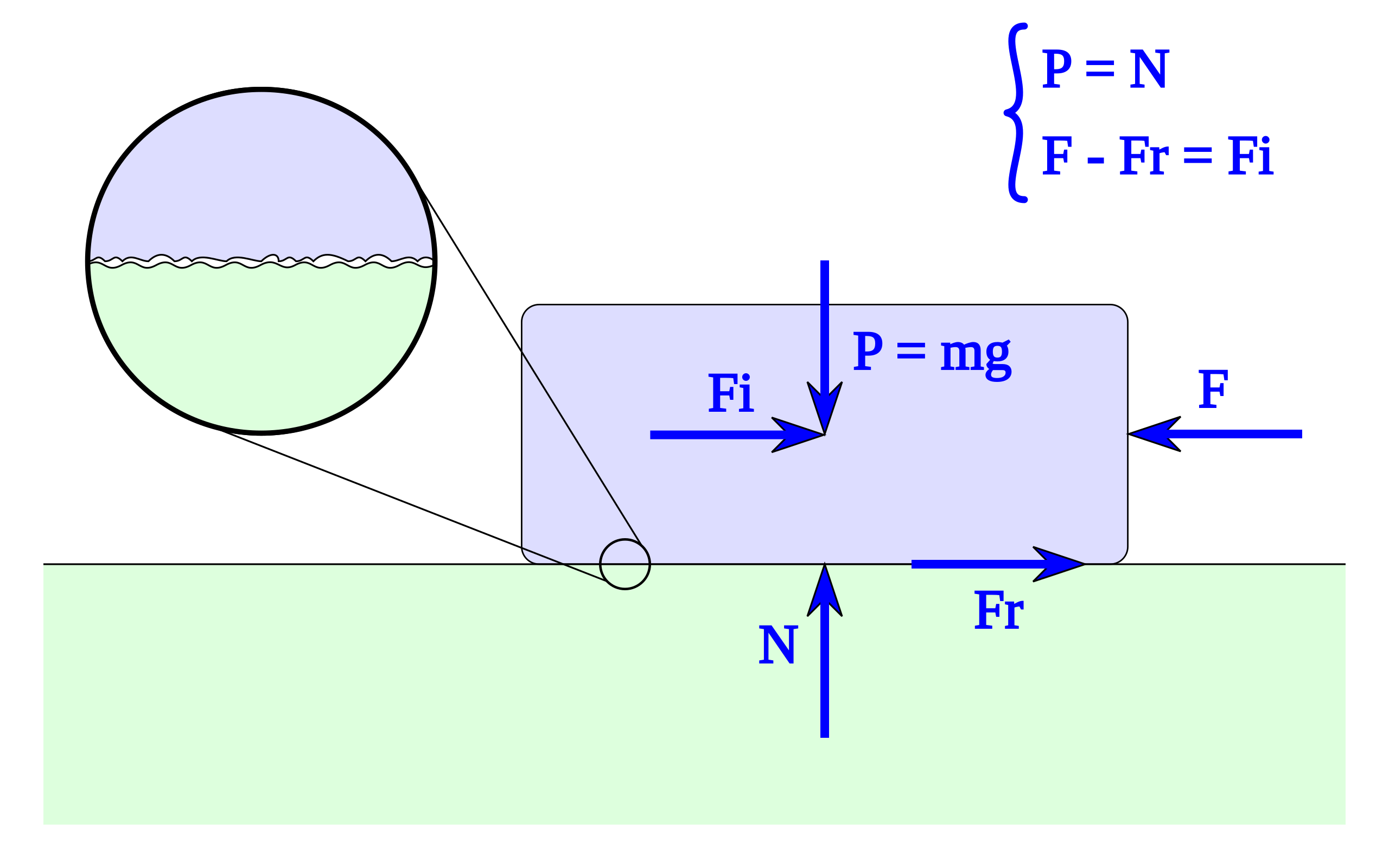

Static Friction: The Gatekeeper of Motion

Static friction is the invisible hand that prevents objects at rest from sliding under applied forces. This resistance is not a fixed value but ranges from zero up to a critical threshold, beyond which motion begins. Its maximum value is calculated as:

Maximum static friction (fs,max) = μs × N

- μs: Coefficient of static friction (varies by material pair and surface conditions)

- N: Normal force pressing the objects together (typically, the weight in simple cases)

Static friction’s responsive nature allows it to match the externally applied force up to its limit—only then does slipping commence. The distinction between static and kinetic friction is fundamental: it typically takes more force to initiate motion than to maintain it, which is why moving a stationary box is harder than keeping it gliding across a floor.

Kinetic Friction: Motion in Progress

Once relative motion begins, static friction is replaced by kinetic friction, also called dynamic or sliding friction. This force, usually smaller than its static counterpart, is given by:

Kinetic friction (fk) = μk × N

- μk: Coefficient of kinetic friction

Kinetic friction is remarkable for its consistency: in many common cases, it doesn’t vary significantly with speed, at least for non-extreme velocities. However, at micro and nano scales, or with certain soft materials (like rubber), deviations can be strong, with friction increasing or decreasing with velocity depending on the system.

On a practical level, kinetic friction is the force that slows a hockey puck across the ice, causes wear on moving machine parts, and determines how fast brakes can bring a vehicle to a halt. Its precise behavior is crucial in engineering, manufacturing, and safety design.

Coulomb Friction: The Classic Model

The Coulomb friction model provides a simple yet effective framework for calculating dry frictional forces in many engineering and physical scenarios. According to this model, the maximum frictional force between two surfaces before sliding occurs is:

Frictional force (Ff) ≤ μ × N

- Ff: Frictional force, acting opposite to potential or actual motion

- μ: Empirical coefficient of friction (static or kinetic, depending on the movement)

- N: Normal force (perpendicular to the contact surface)

The Coulomb model’s strength lies in its simplicity and its wide applicability, despite the underlying physics being far more complex. In real-world applications, the value of μ is determined through experiment, not calculation, and depends on surface texture, cleanliness, material properties, and external conditions like temperature and humidity.

Limitations of the Coulomb model emerge with certain materials, very low or high velocities, soft surfaces, or when strong adhesion dominates (as with tapes or rubber). In such cases, more sophisticated theoretical frameworks are necessary.

Coefficient of Friction: Definition, Dependence, and Measurement

The coefficient of friction (COF) is a dimensionless quantity, symbolized by μ, that encapsulates how much frictional resistance exists between two specific surfaces. It is uniquely defined for every material combination and for both static and kinetic scenarios:

- μs: Coefficient of static friction (before movement)

- μk: Coefficient of kinetic friction (during movement)

Typical values of μ range broadly:

- Metals on metals: 0.3–1.0 (dry), lower when lubricated

- Rubber on dry surfaces: 1.0–2.0

- Teflon (PTFE) on Teflon: As low as 0.04

- Graphite on graphite (superlubricity): Below 0.01

Contrary to what some may think, the coefficient of friction is not a universal ‘material property’ but rather a ‘system property,’ sensitive to factors like surface roughness, environmental conditions, speed, temperature, and the presence of contaminants or lubricants.

Measurement of μ is straightforward in the laboratory: one measures the normal force and the force required to initiate or maintain sliding. However, real-world conditions can render values highly variable, and so tables of coefficients must be interpreted as guidelines rather than absolute numbers.

Fluid Friction and Lubrication

When surfaces are separated by a fluid layer (gas or liquid), a different regime of friction emerges—fluid friction. This resistance depends on the viscosity of the fluid and the relative speed and area of interaction between the layers.

Lubrication leverages this principle to minimize wear and friction in mechanical systems, using oils, greases, or even specialized fluids to create a buffer between moving parts. The effectiveness of lubrication is why your car engine doesn’t seize up and why artificial joints can mimic the smooth movement of natural ones.

In many natural systems, biological lubricants like synovial fluid in joints or mucus between organs dramatically reduce friction, enabling movement and health.

Origin and Modern Theories: Microscopic Insight and the Role of Impurities

Centuries of research have gradually revealed that friction has its roots not only in surface roughness but also in fundamental atomic and molecular interactions. Early models, like those of Amontons, imagined surfaces as gear-like arrays interlocking with each other. However, when examined at the atomic level, perfectly mismatched surfaces (like two different crystal lattices) theoretically would exhibit no static friction.

The breakthrough insight in recent decades is that real-world surfaces are never ‘perfectly clean.’ Instead, a thin layer of contaminants—molecules from the environment, dust, even water vapor—settles between surfaces. These ‘grains’ act as microscopic wedges that become trapped in the valleys and grooves of both surfaces, effectively linking them and preventing easy relative motion.

Modern analytic theory and computer simulations confirm that this ‘surface grime’ is responsible for the ubiquitous presence of static friction, in alignment with Amontons’ classical laws. This understanding is now a cornerstone for both physics and engineering, helping explain persistent puzzles and enabling better friction management in technology.

The Modified Coulomb Model in Engineering Applications

In engineering simulations, especially for systems like seabed interactions, pipelines, and buoyant structures, the classic Coulomb model is often adapted to suit computational needs and represent complex reality. For instance, software like OrcaFlex employs a modified Coulomb model where

- Δcrit = (μ × R) / (ks × a)

- ks: Shear stiffness

- a: Contact area

This approach enables engineers to model transitions from rest to motion realistically, account for damping, and manage complex geometries such as lines, buoys, and surfaces in subsea equipment.

Friction coefficients for such contacts are typically specified based on experimental data for the particular materials, and can differ for lateral and axial directions. Advanced models may further decouple these components and handle dynamic updates as objects move, making simulations more faithful to reality.

Instabilities, Nonlinearities, and Dynamic Phenomena

Friction is notorious for producing a broad spectrum of dynamic behaviors—ranging from simple, predictable resistance to sudden slips, squeals, and even paradoxical effects.

- Stick-slip motion: A common instability where surfaces stick until enough force builds up, then slip abruptly—responsible for squeaking brakes and the ‘song’ of a glass harp.

- Decreasing friction with velocity: In some systems, friction drops as speed increases, leading to oscillations or fluttering.

- Self-organized structures: Continuous sliding can cause the formation of new, adaptive structures at contact interfaces, sometimes reducing friction over time (tribofilms).

- Painlevé paradoxes: Certain configurations with Coulomb friction yield theoretically unsolvable or counterintuitive behaviors.

Advanced simulation methods and experimental observations continue to discover and explain these phenomena, guiding improvements in industrial design and maintenance.

Friction in Everyday Technology and Nature

The profound utility of friction is readily visible in countless technological applications:

- Automotive brakes: Relies on high-friction materials (pads/discs or drums) to convert kinetic energy to heat, enabling rapid stopping.

- Railroad traction: Ensures wheel adhesion to rails for controlled acceleration and braking.

- Adhesion and grip: Sticky pads, tires, and specialized coatings maximize friction for safety and performance.

- Bearings and rolling elements: Transform sliding friction into the much lower rolling resistance, improving efficiency and longevity.

In natural systems, friction is just as vital—for walking, grasping, and even chewing food. Biological adaptations, such as joint cartilage and natural lubricants, minimize frictional wear and optimize energy use.

Special Cases: Superlubricity and Unusual Friction Regimes

Under certain conditions, materials can achieve ‘superlubricity,’ where friction coefficients approach zero. Graphite and highly ordered ceramics, for example, can slide with astonishing ease due to their layered atomic structures.

On the other end of the spectrum, engineered surfaces or substances like sticky rubbers can sustain friction coefficients well above one, defying the simplistic expectation that μ must always be less than one. This enables applications like racing tires and specialty gripping tools.

Even more exotic effects include the possibility of negative friction coefficients under specific nanoscale conditions, and the use of acoustic or vibratory energy as a form of ‘lubrication.’

Real-World Measurement, Tables, and Variability

Despite the sophistication of friction theory, practical engineers and scientists still depend heavily on empirical tables and experimental measurements. These present the typical static and kinetic coefficients for hundreds of material pairs—ranging from metals, plastics, and ceramics to biological tissues.

However, even under controlled conditions, measurements can show significant variability due to surface roughness, contamination, temperature changes, and geometric effects. For instance, the coefficient of friction for steel-on-steel can differ by a factor of two or more depending on whether surfaces are lubricated, polished, or oxidized.

The same is true in biological systems, where fluids, proteins, and wear particles continually modulate friction at every joint or contact point.

Friction Theory Beyond Physics: Applications in Innovation and Change Management

Interestingly, the idea of ‘friction’ has also been borrowed into business and psychology as a powerful metaphor for resistance to change or innovation. Thought leaders and behavioral scientists have proposed frameworks identifying different types of ‘friction’ that can impede adoption of new ideas, products, or practices:

- Inertia: The default tendency to stick with familiar routines or environments, making major changes harder to embrace.

- Effort: The perceived or real cost of implementing a change, whether logistical, financial, or emotional.

- Reactance: Psychological resistance that surfaces when individuals feel pressured or manipulated toward change.

- Emotion: The latent feelings—nostalgia, anxiety, uncertainty—that can make even objectively superior options unappealing.

Addressing these ‘psychological frictions’ has proven to be as important as amplifying the ‘fuel’ (incentives or value) behind innovations. Identifying and removing barriers—such as making transitions simpler, reducing effort, or respecting emotional attachments—can be more effective than simply trying to make new ideas more attractive.

This conceptual spillover from physical science reminds us: friction, in all its forms, is an inevitable part of both natural and social worlds, requiring thoughtful understanding and strategic management.

Advanced Mathematical Models: Beyond Simple Equations

While classical equations suffice for many purposes, real frictional behavior often requires more advanced mathematics. Models must account for:

- Nonlinear force-deflection curves, especially in polymers and rough surfaces.

- Velocity- and temperature-dependent effects, critical at high speeds or in lubricated systems.

- Coupled and decoupled friction models (e.g., lateral versus axial friction in cables or lines).

- Dynamic updating of target positions and force thresholds, as seen in sophisticated engineering simulations.

- Damping contributions and mass effects, especially for large or rapidly moving bodies.

Modern computational tools now allow for the simulation of frictional systems with thousands or millions of interacting elements, providing detailed predictions for engineering, biomechanics, geosciences, and materials science.

The Continuing Mysteries and Future Directions

Despite centuries of progress, friction remains in some ways an unsolved problem in physics—especially at the interface of hard and soft materials, or under extreme conditions. Research continues to push boundaries, both in fundamental understanding and in the creation of new materials and technologies to control, harness, or minimize friction.

From enabling new modes of transportation and energy efficiency to guiding the design of smart prosthetics and nanomachines, friction theory will remain a vibrant, challenging, and exciting field for generations to come.

Friction occupies a unique place in science and technology as both a challenge and a resource, intricately woven into countless aspects of our world. Its study bridges the smallest scales of molecular physics with the largest considerations of engineering, safety, and even organizational change. As we’ve seen, friction is much more than ‘just’ a force—it’s a complex, variable, and deeply fascinating phenomenon. Appreciating its nuances not only enriches our understanding of the physical universe but also empowers us to make smarter choices, whether we’re engineering machines, optimizing systems, or simply trying to overcome resistance—literal or metaphorical—in our everyday lives.