- Stepper-motor control enables precise and efficient positioning.

- Modern techniques such as microstepping and closed-loop feedback improve performance.

- Selecting the right driver and motion profile is essential.

The world of automation and robotics is experiencing unstoppable growth, powered by technologies that enable precise, repeatable motion. One of the core components in many mechatronic systems is the stepper motor, whose versatility and ease of control have earned it a prominent place in industrial applications, 3-D printing, CNC, robotics, medical instrumentation, and countless positioning systems.

Efficient, precise, and robust control of a stepper motor is essential to fully exploit its potential. In recent years, control techniques and available drivers have evolved enormously, overcoming traditional limitations such as vibration, noise, excessive heating, or missed steps.

What is a stepper motor?

A stepper motor—also known as a “stepper”—is a type of DC electric motor that divides one full revolution into a predetermined number of equal steps. Each of these steps corresponds to a precise shaft rotation, making stepper motors especially useful for positioning tasks that demand high accuracy without the need for a feedback system.

These motors work by applying electrical pulses to different phases or coils, generating magnetic fields that move the rotor in a controlled way. Various technologies and configurations allow the stepper motor to be tailored to the specific needs of each application.

Main types of stepper motors

Within the stepper-motor family there are three main types, each suited to different uses:

- Variable reluctance: The rotor is multipole iron and the stator has wound coils. They offer very fast response but have zero holding torque when not energized. They are mainly used where high speed and low inertia are required.

- Permanent-magnet: The rotor contains permanent magnets, allowing it to maintain torque even when de-energized. Typical step angles are 7.5°, 11.25°, 15°, 18°, 45°, or 90°, depending on internal construction, and they are suitable for loads that must not shift if power is lost.

- Hybrid: Combines features of the two above: an axially magnetized concentric permanent-magnet rotor with many teeth on both rotor and stator. The hybrid stepper is the most popular choice for applications requiring precision (1.8° per step) and high torque.

The number of leads varies with the internal wiring. Unipolar motors may have five or six leads (one or two commons), while bipolar motors typically have four leads and require reversing current through each coil. This makes control more complex but allows greater efficiency.

How they work: control principles and sequencing

The basic principle is to energize the stator coils in a precise sequence so that magnetic attraction advances the rotor step by step.

In bipolar motors, for instance, control is based on inverting current flow through each coil using an H-bridge circuit, which lets you change the supply direction and therefore advance the rotor in the desired direction.

Sequencing—the order in which coils are energized—is fundamental to correct operation. There are many phase tables or sequences depending on motor type and control mode: full-step, half-step, microstepping, and so on.

| Step | Coil A Terminal 1 | Coil A Terminal 2 | Coil B Terminal 1 | Coil B Terminal 2 |

|---|---|---|---|---|

| Step 1 | +Vcc | −Vcc | ||

| Step 2 (half-step) | +Vcc | −Vcc | +Vcc | −Vcc |

| Step 3 | +Vcc | −Vcc | ||

| Step 4 (half-step) | −Vcc | +Vcc | +Vcc | −Vcc |

| Step 5 | −Vcc | +Vcc | ||

| Step 6 (half-step) | −Vcc | +Vcc | −Vcc | +Vcc |

| Step 7 | −Vcc | +Vcc | ||

| Step 8 (half-step) | +Vcc | −Vcc | −Vcc | +Vcc |

Rotation speed is determined by the relationship between control-pulse frequency and the motor’s pole count (N = 60 × f / n), where N is speed in RPM, f is pulse frequency, and n is the number of poles.

Advantages and limitations of stepper motors

The chief attraction of stepper motors is their straightforward control and their ability to hold an absolute position without extra sensors or feedback loops. They are ideal for tasks requiring precise, repeatable movement at a good cost-to-performance ratio.

Other key advantages include:

- Low cost compared with alternatives such as servomotors.

- High reliability with brushless operation, reducing maintenance.

- Direct pulse-and-direction control, easy to implement with simple drivers.

- High holding torque at standstill (in many models).

Natural limitations include:

- Limited speed range, especially in open-loop configurations.

- Possible missed steps under excessive loads or incorrect sequencing.

- Risk of vibration and resonance at certain frequencies, the “mid-range instability.”

- Noise and heating with older control techniques.

Structure of a stepper-motor control system

A typical control system for a stepper motor consists of several elements:

- Motion-profile generator: Defines the desired path, speed, and acceleration. It may be a microcontroller, PLC, or external pulse generator.

- Sequencing logic: Determines the order and strength of pulses for each coil, matching movement to the profile.

- Current controller: Ensures that actual coil current matches the commanded value, compensating for effects like inductance and back-EMF.

- Amplifier: Delivers the required voltage and current to each coil as demanded by the controller.

Most modern applications use bipolar drivers because they offer higher efficiency and enable advanced techniques like microstepping.

Control methods: the evolution of stepper control

Open-loop control

The traditional, simplest, and most widespread method is open-loop control. Here, the desired position is translated into a pulse sequence that energizes the motor coils in the correct order. The motor moves exactly one step per pulse without verifying that the movement actually occurred.

The most common open-loop techniques are:

- Full-step: Alternate energizing of phases produces four positions per electrical cycle.

- Half-step: Alternates between single-phase and dual-phase energizing, doubling positions and smoothing motion.

The standard “pulse & direction” scheme, widely used in CNC and automation, generates one pulse per step advance and a direction signal to set rotation sense.

Microstepping: extreme smoothness and resolution

To overcome the limits of full- or half-step modes, microstepping feeds the coils with sinusoidal or quasi-sinusoidal currents instead of simple ON/OFF signals. This divides the physical step even further, achieving up to 256 microsteps per full step.

Benefits of microstepping include:

- Much smoother motion, eliminating most noise and vibration.

- Higher effective resolution, enabling fine positioning.

- Reduced resonance and lower risk of missed steps at certain frequencies.

However, greater mechanical resolution does not automatically mean greater absolute accuracy. The real position can deviate from theory due to external forces, friction, or inertia—up to about 0.15 mechanical degrees in a 1.8°-per-step motor, even with microstepping.

Variable-speed control and motion profiles

The speed/position profile (ramp) used for starting or stopping is crucial to avoid issues such as mid-range instability or missed steps from overly aggressive acceleration.

Profiles such as trapezoidal, S-curve, and custom ramps adapt movement to load conditions and resonance, improving both reliability and service life.

Stepper dynamics: response to loads and acceleration

When a coil is energized, the rotor moves to an equilibrium position set by the angle between the stator’s magnetic field and the rotor. External forces (acceleration, friction, unexpected loads) can cause phenomena such as:

- Ringing: Oscillation as it tries to settle—like a ball rolling in a bowl.

- Missed steps: If load or acceleration exceeds maximum torque, the motor fails to reach the commanded position and “slips.”

Microstepping and proper ramp selection greatly mitigate these issues, but critical applications often employ more advanced techniques.

Current control: ensuring the right response

Coil inductance and back-EMF make it hard to keep the desired current at all times. A good current-control system is vital for linearity, torque, and motor protection.

Fixed off-time method

This drives the coil at maximum voltage until the desired current is reached, then switches it off for a fixed time. It’s simple and inexpensive, widely used in low- to mid-range controllers. But it loses precision when the target current decreases, potentially causing overheating, noise, and momentary torque loss.

Digital closed current loop (PI loop)

High-end controllers use a proportional-integral loop to continuously adjust coil voltage so actual current matches the target. This provides precise control under all conditions, maximizes efficiency, and sharply reduces noise, vibration, and heat.

PI-loop control is common in premium systems, where each phase has its own regulator and current sensing is digital and robust.

Protection and adjustment features

Many modern drivers include key extra functions:

- Stall detection: Detects when the motor is not following the step sequence correctly, either via an encoder (external feedback) or internal electronics (back-EMF analysis). Electronic detection is not 100 % reliable but avoids encoder cost.

- At-Rest function: Reduces current when the motor is idle, limiting heat without sacrificing holding torque.

- Over-current, over-voltage, and over-temperature protection: Prevents damage to both motor and driver.

Closed-loop control: bringing the stepper closer to a servo

The current trend in demanding applications is closed-loop control, combining stepper advantages with servo benefits. With a high-resolution encoder, position is actively controlled via a PID loop.

Closed-loop advantages include:

- No missed steps, even under varying loads and acceleration.

- Higher energy efficiency: only the necessary current is applied at any time.

- Resolution and accuracy independent of mechanical step angle: defined by the encoder rather than the motor’s physical step.

- Ability to use higher accelerations without risk of desynchronization.

The “closed-loop stepper” concept is spreading rapidly, and more manufacturers now offer it in their high-end products.

Common driver and controller configurations

The stepper-driver ecosystem has grown considerably, offering different architectures with varying integration and functionality:

- Control ICs with integrated power stage: Small chips containing both control logic and power driver, accepting pulse-and-direction signals directly. They are the cheapest option for simple applications and low-current motors (typically up to 2 A per phase).

- Control ICs with outputs for external amplifiers: Similar but able to drive higher-power stages or advanced setups, including digital current loops and encoder support.

- Controllers with integrated motion profiling: Provide full motion control, trajectory generation, and microstepping, commanded from a microcontroller or PC via protocols such as SPI, RS-232, CAN, etc.

- Ready-to-use drivers and modules: Boards or modules that integrate all electronics; advanced models can program profiles, run closed loop, host user code, and offer industrial connectivity (EtherCAT, CANopen, etc.).

Selecting a stepper motor: key characteristics

Whether you’re automating a 3-D printer, CNC, lab machine, or industrial application, choosing the right motor and driver depends on several factors:

- Number of phases: Two-phase bipolar is most common, but three- or five-phase motors exist for special cases.

- Size and torque: The well-known NEMA series (NEMA 17, NEMA 23, etc.) standardizes dimensions; torque depends on construction and rated current.

- Step angle: Defines how many physical steps per revolution (typical: 1.8° per step, i.e., 200 steps per rev).

- Control type: Depending on whether open loop, closed loop, custom profiles, or industrial connectivity is required.

Typical applications and practical considerations

Stepper motors are ubiquitous in high-precision applications such as:

- 3-D printers: E.g., the popular NEMA 17 for extruders and axes.

- CNC machines and mills: Enable millimetric, repeatable positioning.

- Medical and laboratory instrumentation, where reliability and exact motion control are critical.

- Industrial automation, robots, and linear actuators.

When implementing stepper-based systems, keep in mind:

- Motor heating if powered continuously; At-Rest functions help mitigate this.

- The possible need for simulators or test benches at start-up to rule out wiring or sequencing errors and avoid over-current damage.

- Working-current adjustment: Start low and increase until the required torque is reached, but never exceed the manufacturer’s rated value.

- Maximum allowable speed: Most stepper motors cannot exceed about 625 Hz pulse frequency without risking erratic behavior or missed steps.

Comparison with other positioning systems

Comparing stepper motors with technologies like DC motors with encoders or brushless (BLDC) motors:

- Steppers excel in simplicity and low cost for moderate-precision applications where occasional missed steps are not critical.

- Brushless motors offer more torque and speed, plus natural closed-loop operation, but are more complex and expensive.

- Traditional DC motors require a control loop for positioning, adding complexity and cost, but they can operate over a wider speed range.

The stepper finds its sweet spot in open-loop systems, though closed-loop control is rapidly expanding its domain.

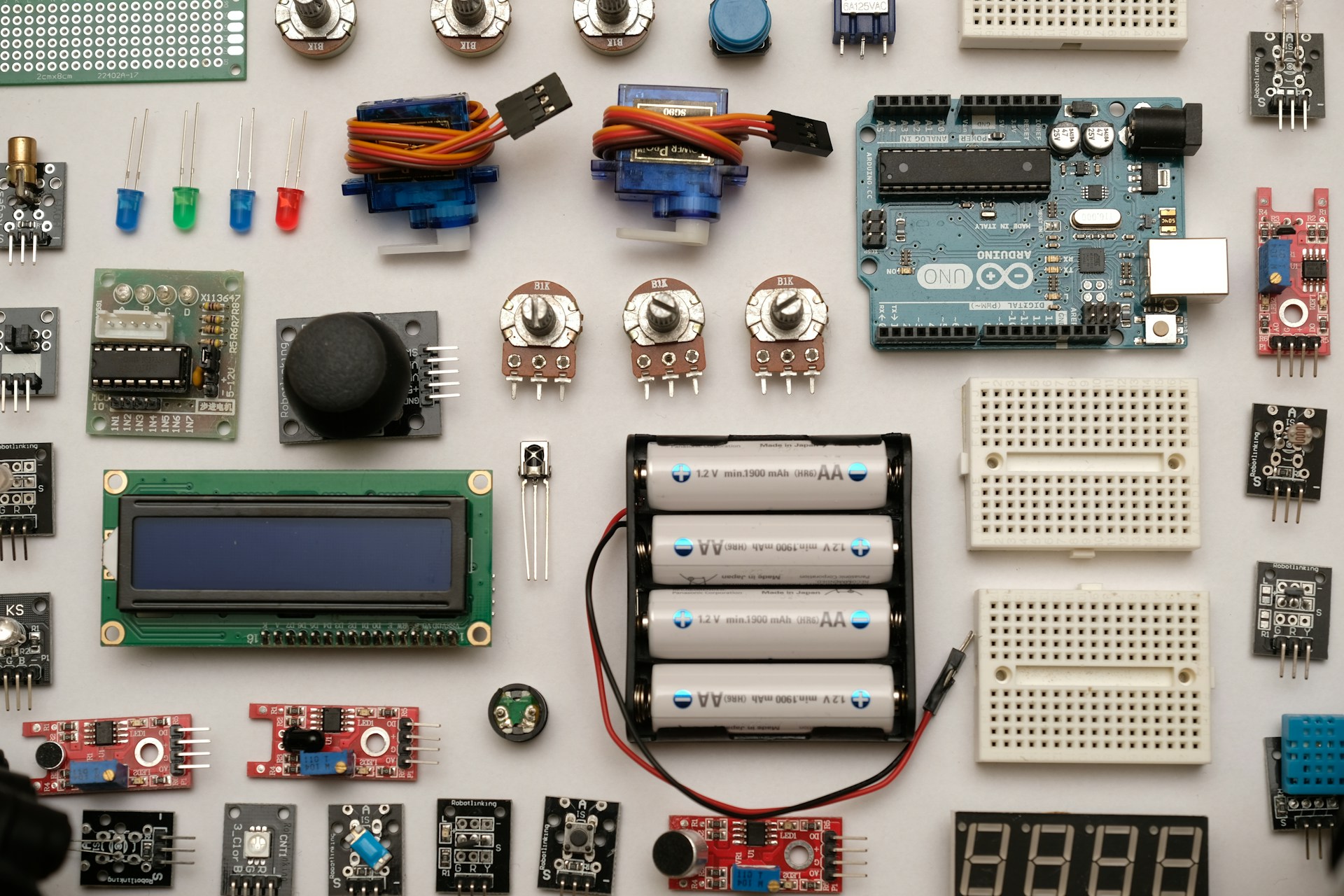

Practical example: integrating an EasyDriver with Arduino

One of the most popular drivers for electronics and educational robotics projects is the EasyDriver. This module simplifies the connection between a microcontroller and the motor, enabling pulse-and-direction control and easy microstepping adjustment. To learn more about the EasyDriver and its variants, you can visit the relevant section on Amazon.

The Arduino community offers detailed guides and many specialized libraries for stepper-motor management. Among the most used are AccelStepper and Stepper.h, which simplify programming and enable advanced functions such as acceleration ramps, speed control, and simultaneous operation of multiple motors.

Legal and commercial aspects

Keep in mind that many brand names and acronyms are property of well-known manufacturers. Companies such as igus, Allen-Bradley, Baumüller, Beckhoff, Festo, Siemens, and others own registered trademarks and licenses in various markets. Before purchasing or using compatible products, verify real compatibility and available support.

Companies like igus offer comprehensive solutions for stepper and DC-motor control, clearly differentiating their own products from those of third-party manufacturers. This distinction is key to avoiding incompatibilities and support issues.

Trends and the future of stepper-motor control

Stepper-motor technology and its control systems are constantly evolving. The rise of closed-loop control, digital current regulation, and integration with advanced industrial buses (EtherCAT, CANopen, Profinet, etc.) define the immediate future.

Moreover, modular, programmable systems capable of running user code and linking with IoT platforms are democratizing access to advanced applications for all kinds of users—from industrial manufacturers to makers and robotics enthusiasts.

Frequently asked questions about stepper-motor control

- Can I use a unipolar motor as a bipolar one? Yes, in most cases, by disconnecting the common wire and powering the coils directly. Check the datasheet to confirm compatibility.

- What happens if the pulse frequency is too high? The motor may stop moving, vibrate without turning, miss steps, or even reverse if its limit is exceeded.

- Is an encoder always necessary? No. Encoders are only essential in closed-loop systems or when active monitoring and correction of position are required. Standard applications can run open loop.

- Which microcontrollers are compatible? Virtually any basic microcontroller (Arduino, ESP32, STM32, etc.) can generate stepper-control signals using appropriate libraries and shields.

Stepper-motor control is one of the richest and most versatile fields in automation and mechatronic engineering. Its success lies in achieving precise, repeatable positioning using techniques that range from the very basic to cutting-edge intelligent systems. As control electronics, algorithms, and integration with other technologies advance, stepper-motor applications continue to grow across both industrial and maker communities. Proper selection and tuning of control techniques, combined with correct motor and driver sizing, will ensure efficient, quiet, and reliable operation for any system that demands millimetric precision and absolute repeatability.

“`